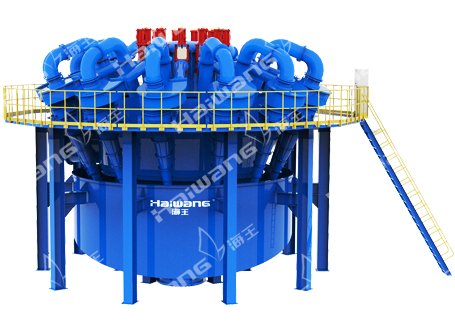

The hydrocyclone takes water as medium to classify and separate mineral particles in the centrifugal force field with tens to hundreds of times acceleration of gravity. According to its different application, it can be divided into grinding classification hydrocyclone, ultrafine classification hydrocyclone, desliming hydrocyclone, concentrated hydrocyclone and so on.

Haiwang has been committed to the R&D of new technology and equipment for high efficiency and low consumption swirl separation. Through various patented technologies, such as helical radial alignment technology for the feed particle, short-circuit current directional suppression technology, internal swirl turbulent energy consumption reduction technology, as well as volute pre- classifying feed structure, spiral line feed structure, multi-cone structure, flat bottom structure, on-line adjustable spigot and other patented structures, the separation efficiency of hydrocyclone is improved and the energy consumption of equipment is reduced effectively.