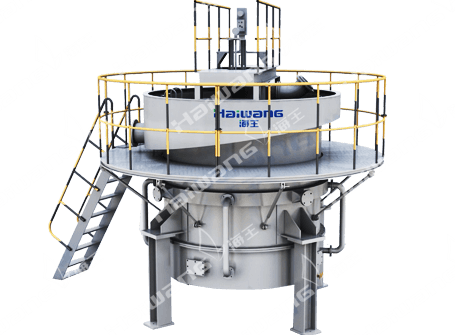

FBS® fluidizing bed separator (Fluidizing Bed Separator) is a new type of separation equipment developed by Weihai Haiwang Cyclone Co., Ltd., in cooperation with the Institute of Process Engineering of the Chinese Academy of Sciences, which, combines fluidization technology and gravity interference sedimentation separation technology in turbulent flow field for the first time. It can realize the high-effeicient separation or purification of coarse slime, mining sands and pyrites etc fine particle materials. It is identified by Shandong Province scientific and technological achievements that it has reached the domestic leading technical level, which is listed as Shandong province major energy-saving technology industrialization project successively and national torque planning project, entitled with two national practical patents and one Shandong province science and technology progress prize.