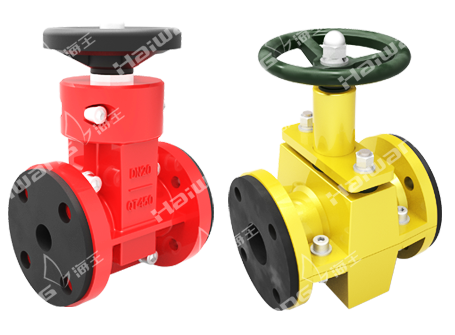

Pinch valve uses pneumatic, electric, manual or hydraulic driving mode to squeeze the casing, so as to achieve the function of ON/OFF and regulation. In the open position, the valve forms a channel without fluid resistance, making it become part of the pipeline. In the closed position, the two compression plates tighten the hose in the central position.

The modular design of FG series valves has three main parts: elastic hose, valve body and actuator. The valve sleeve is the only part in contact with the tube through the medium, which plays a role in corrosion resistance, wear resistance and bearing pressure.