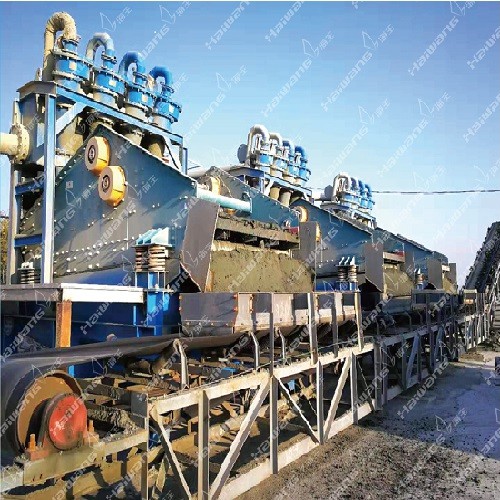

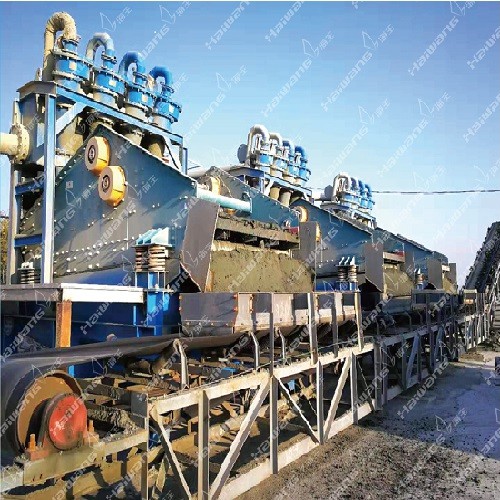

Haiwang sand extraction equipment is used in mine tailings sand washing and waste stone mechanical sand making process

As the natural resource with the greatest demand for infrastructure construction, sand and gravel aggregates have changed from natural collection to mining and manufacturing in recent years. Among them, mine tailings sand washing and waste rock mechanical sand making account for a certain proportion of the supply of sand and gravel aggregates.

1. Tailings sand washing

Sand washing from mine tailings is an important way for tailings recovery and reuse. After the ore is crushed, ground, and classified, the remaining product after separation of useful minerals is the tailings. Tailings produced by different ore properties or different beneficiation processes have certain differences in particle shape and particle gradation. Through suitable sorting technology and equipment, the particles with suitable size in the tailings can be extracted and used as construction sand.

System process: The tailings slurry is pumped to the cyclone to be concentrated and classified. The coarser and denser grit material is fed to the vibrating dewatering screen for dehydration. The dehydrated product is fine sand, and the moisture content can be controlled at 18 %about.

The material under the sieve can be discharged in a closed loop or along with the overflow of the cyclone according to the composition of the incoming material and the product size requirements. The overflow of the cyclone is mainly the fine mud in the tailings. The removal of the fine mud is beneficial to improve the quality of the fine sand product.

2. Waste stone mechanical sand making

In the process of mining ore, a large amount of waste rock will be stripped away. The stacking of waste rock occupies a large area and has a certain impact on environmental protection. The application of mining waste rock mechanical sand making technology can not only protect the environment, but also create certain economic benefits. The sand-making process of mine waste rock refers to the process of crushing the waste rock to a suitable particle size, and then obtaining a series of products such as aggregate, coarse sand, and fine sand after grading.

System process: The crushed waste rock is processed by a grading screen, and the material on the screen is the aggregate product (the particle size can be adjusted according to market demand). The material under the screen enters the coarse sand sorting process. The coarse sand sorting generally adopts a bucket sand washing machine. The product of the sand washing machine is coarse sand after being dehydrated by a dewatering screen. The remaining materials processed by the bucket sand washer then enter the cyclone + dewatering screen fine sand recovery system.

3. Key equipment

Haiwang XS series bucket sand washing machine is mainly used for machine-made sand washing, fine aggregate desliming and other operations. The equipment combines the traditional grinding wheel bucket with the trough hydraulic classifier to solve the problem of the impact of the grinding wheel bucket disturbance on the classification and optimize the overflow material structure, improve the product recovery rate, the recovery rate of more than 0.15mm is more than 80%, The product gradation is reasonable, the fineness modulus is moderate, and the mud content is small.

Haiwang high-efficiency sand washing cyclone adopts a patented feeding method and cone angle structure, and is mainly used in mine tailings sand washing and desilting of high-content debris powder. It has the characteristics of high classification efficiency and small underflow clamps, which solves the problem of high mud/powder content in fine sand recovered from high mud/powder-containing materials.

Haiwang cyclone + dewatering screen fine sand recovery system is mainly used in the fine sand recovery conditions of sand washing wastewater in the tailings sand washing and waste rock sand making process. It has the characteristics of small grading particle size, high fine sand recovery rate, and strong concentration performance. The system has simple process flow, low investment cost, high product quality, low water content and controllable particle size.